- Production hub for FUSO Canter models for European markets for more than 40 years

- All-time production record of 11,800 built trucks in 2023

- Mitsubishi Fuso Truck Europe S.A. (“MFTE”) is one of the largest employers in the region

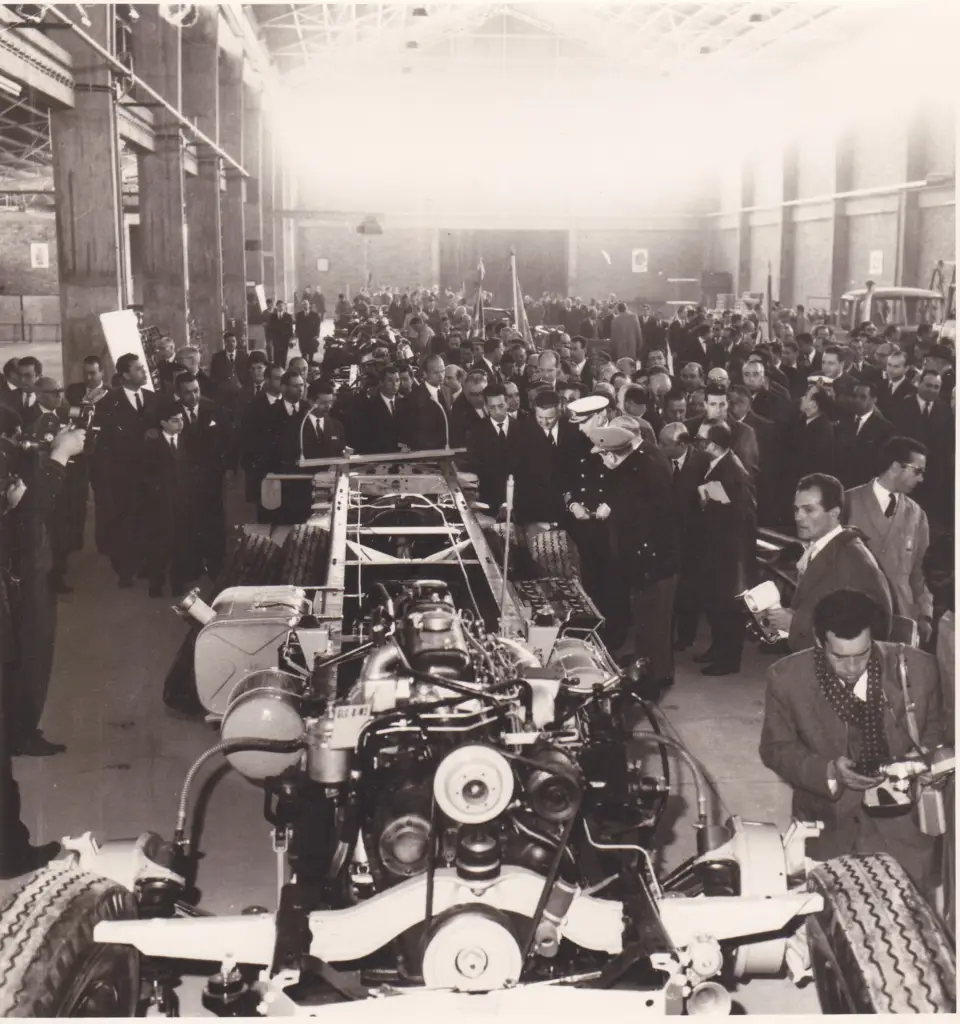

Leinfelden-Echterdingen, Germany/Tramagal, Portugal – The Daimler Truck AG („Daimler Truck“) announces the 60th anniversary of their production facility in Tramagal, Portugal. The plant of Mitsubishi Fuso Truck Europe S.A. (“MFTE”) is one of the largest employers in the region and the third-biggest automobile manufacturer in Portugal. In 2023, the plant built and delivered approximately 11,800 trucks to customers, establishing an all-time production record for the facility. MFTE serves as FUSO’s production hub for the light-duty truck Canter and eCanter for the European markets.

Arne Barden, CEO of MFTE: “The passion and high level of qualification of our workers is astonishing. And with the all-electric eCanter, we drive the transformation – at the same time, our past knowledge and heritage will guide us into the future.”

Tramagal plant history and sustainability focus

In the 60 years since production began, more than 260,000 units have been manufactured in Tramagal – including FUSO’s light-duty Canter, which the plant started producing in 1980. Today, the vehicles assembled at MFTE are shipped to 33 European markets and to Morocco.

The facility in Tramagal was founded in 1964 as a joint venture of the Portuguese family-owned company Duarte Ferreira and the former French truck manufacturer Berliet. Operations began with CKD (completely-knocked-down) assembly for Mitsubishi Fuso Bus and Truck Corporation (“MFTBC”) in 1980. In the following years, the plant produced the FUSO Canter light-duty truck for the Portuguese market as well as the medium-duty Fuso truck, the Mitsubishi L 200 pick-up truck, the L 300 van, and the Pajero.

In 1990, the plant was acquired by the Portuguese import company Mitsubishi Motors Portugal. In 1996, Mitsubishi Motors Corporation took over the plant and decided to focus on the FUSO Canter production. The plant became part of Daimler AG in 2004 after the company’s acquisition of Mitsubishi Fuso’s majority share. In 2017 the plant started the production of FUSO’s first battery-electric eCanter in small series production. Since 2023 the Next Generation eCanter is manufactured in mass production.

Since 2022, the plant has achieved CO2-neutrality on the balance sheet in its operations, thanks to the on-site generation of green electricity and other measures. The plant aims to become a climate-positive facility and is improving their ecological strategy continuously. MFTE is also testing technologies for the local production of green hydrogen. Another measure in the field of sustainability is the reduction of water consumption: MFTE’s new water treatment plant already treats over 60 percent of process water and returns it to the production cycle. At the same time, an optimized rainwater collection system is in the works for more sustainable irrigation of the green areas.

Employer of choice for generations of workers

At the MFTE plant in Tramagal, many workers are long-time employees and there are even three or four generations of a family who have been employed at the plant. Paulo Simão, Head of procurement, is one of them. His father and grandfather worked at MFTE in Tramagal as well. And his son Miguel followed the tradition: He is currently working in maintenance. MFTE focuses on training and development of their employees with regard to the transformation. Last year, MFTE announced their partnership with the Polytechnic Institute of Tomar, Portugal. The new training program providing career prospects for young professionals in the region of Tramagal will start in 2024.