Toyota City, Japan, February 26, 2021―Toyota Motor Corporation (Toyota) has developed a product that packages a fuel cell (FC) system into a compact module and plans to begin selling it in the spring of 2021 or later. The new module will be easily utilized by companies that are developing and manufacturing FC products for wide variety of applications, including mobility such as trucks, buses, trains and ships, as well as stationary generators (referred to hereafter as “FC product companies”).

As various policies for utilizing hydrogen have been adopted in recent years in each country and region and many companies have been entering the market one after another. As a result, the need for hydrogen and FC technologies has been increasing in a variety of applications.

In addition to its effort to popularize FCEVs, Toyota will continue to strengthen its initiatives as an FC system supplier to promote hydrogen utilization through the popularization of FC products together with various FC product companies with the aim of reducing CO2 emissions to curtail global warming and to contribute to the achievement of carbon neutrality.

Toyota has been taking various initiatives toward the creation of a hydrogen society, such as selling the “Mirai” FCEV and the “SORA” FCEV bus, selling FC systems to FC product companies, as well as allowing royalty-free use of its FCEV-related patent licenses. Through these experiences, the company has learned that many companies involved in FC products in a variety of industries are looking for FC systems that can be easily adapted to their own products.

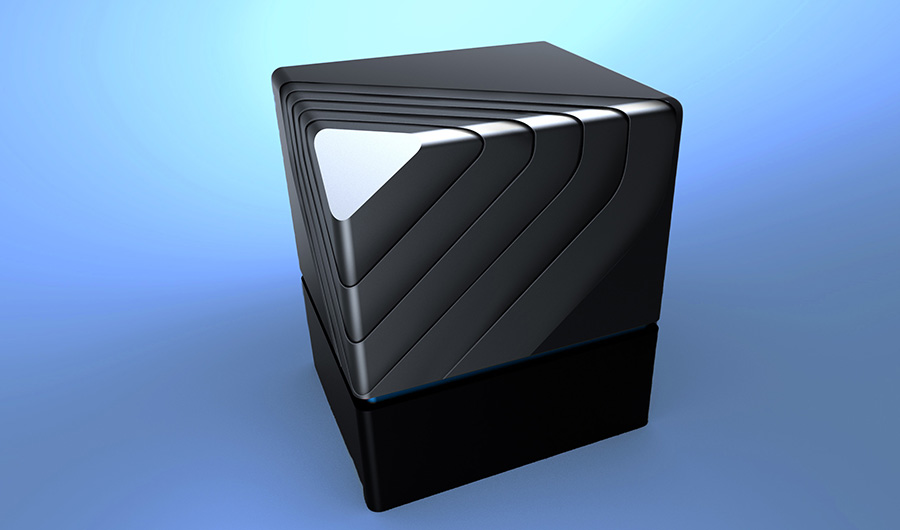

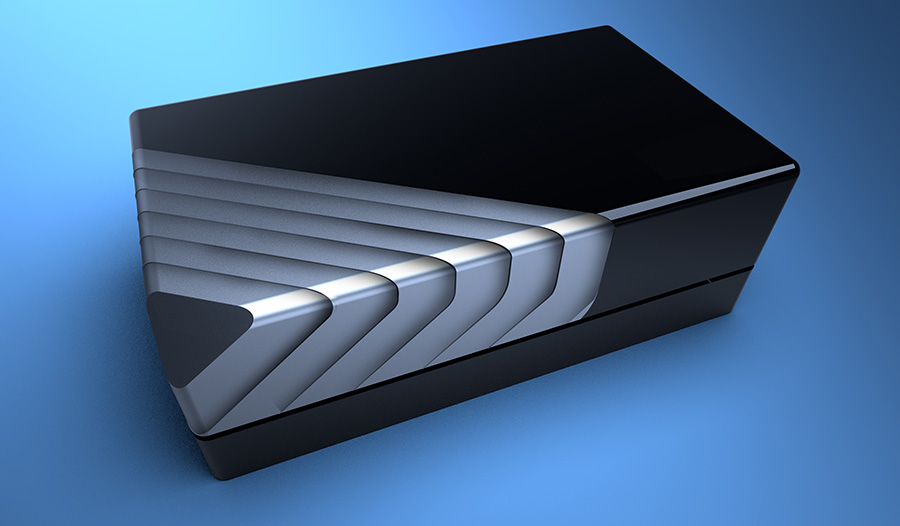

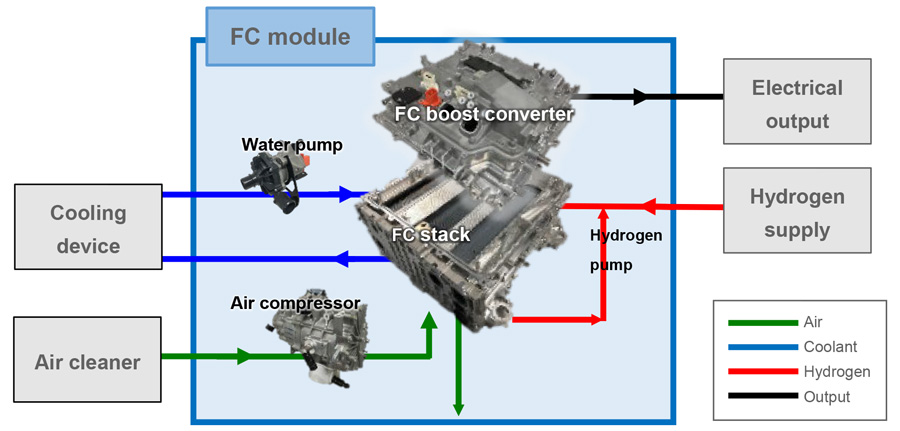

Therefore, to address these needs, Toyota has developed a product that packages individual FC system-related products of second generation Toyota Mirai with enhanced performance, such as the FC stack, as well as components that handle air supply, hydrogen supply, cooling, and power control, into a single compact module. The new module is available in four models―a vertical type (Type I) and a horizontal type (Type II), with rated output of either 60 kW or 80 kW.

FC module overview

| Vertical type (Type I) | Horizontal type (Type II) | |

|---|---|---|

| External appearance |  |  |

| Dimensions (length x width x height) | 890 x 630 x 690 mm | 1,270 x 630 x 410 mm |

| Weight | Approx. 250 kg | Approx. 240 kg |

| Rated output | 60 or 80 kW | 60 or 80 kW |

| Voltage | 400 – 750 V |

Values are target values and are subject to change.

Toyota developed the FC module utilizing technologies it cultivated through its development of FCEVs over many years, as well as the knowledge and expertise accumulated in a variety of usage environments around the world and utilized in the Mirai. The following section describes the specific features of the module:

Highly versatile product lineup and high installability

- The new module has a wide voltage range (400 to 750 V) and can be directly connected to an existing electrical instrument provided with a motor, inverter, and battery, etc., thanks to a built-in, dedicated FC boost converter that simplifies the development and manufacture of FC products. In addition, the system’s modularization greatly improves convenience.

- The four module models can be combined according to the application, flexibly adapting to the output level and amount of installation space available.

- Modularization eliminates the need to create designs for individually installing FC system-related components and to connect individual components. It also integrates and decreases the number of locations the module must be connected to a device, allowing for easy installation.

Schematic example of connecting the FC module to an external device

Excellent safety/reliability and support structure for peace of mind during use

- To ensure safety related to the use of hydrogen and high voltage, the countermeasures cultivated during the development of electrified vehicles such as FCEVs and HEVs were implemented. These measures are based on the basic approach of ensuring that hydrogen does not leak and, in the unlikely event that any leaks should occur, ensuring their immediate detection and stoppage.

- The module was designed to work in a broad range of operating environments, ensuring system operation at low or high temperature, at higher altitude where the oxygen level is lower, and under applications involving vibration.

- When FC product companies decide to utilize the module, they have the option to request the support of highly experienced engineers in determining optimal layout and design according to fuel economy, usage duration, and running cost, etc.

Excellent basic performance (high output and economical efficiency)

- Capitalizing on the characteristics of the compact Toyota FC system, which eliminated the humidifier by circulating the water generated during power generation inside the FC stack, the new module has achieved a world-class, top level output density per unit volume.

- The maintenance requirements of the new module are simple and infrequent, helping to reduce the total cost, from procurement and usage, to disposal.